To Be Demonstrated at the Automate Show, the OG09A Is a 9MP High-Resolution Global Shutter Sensor with a 1-inch Optical Format Featuring PureCel®Plus‑S Technology That Targets High-Speed Machine Vision Requirements

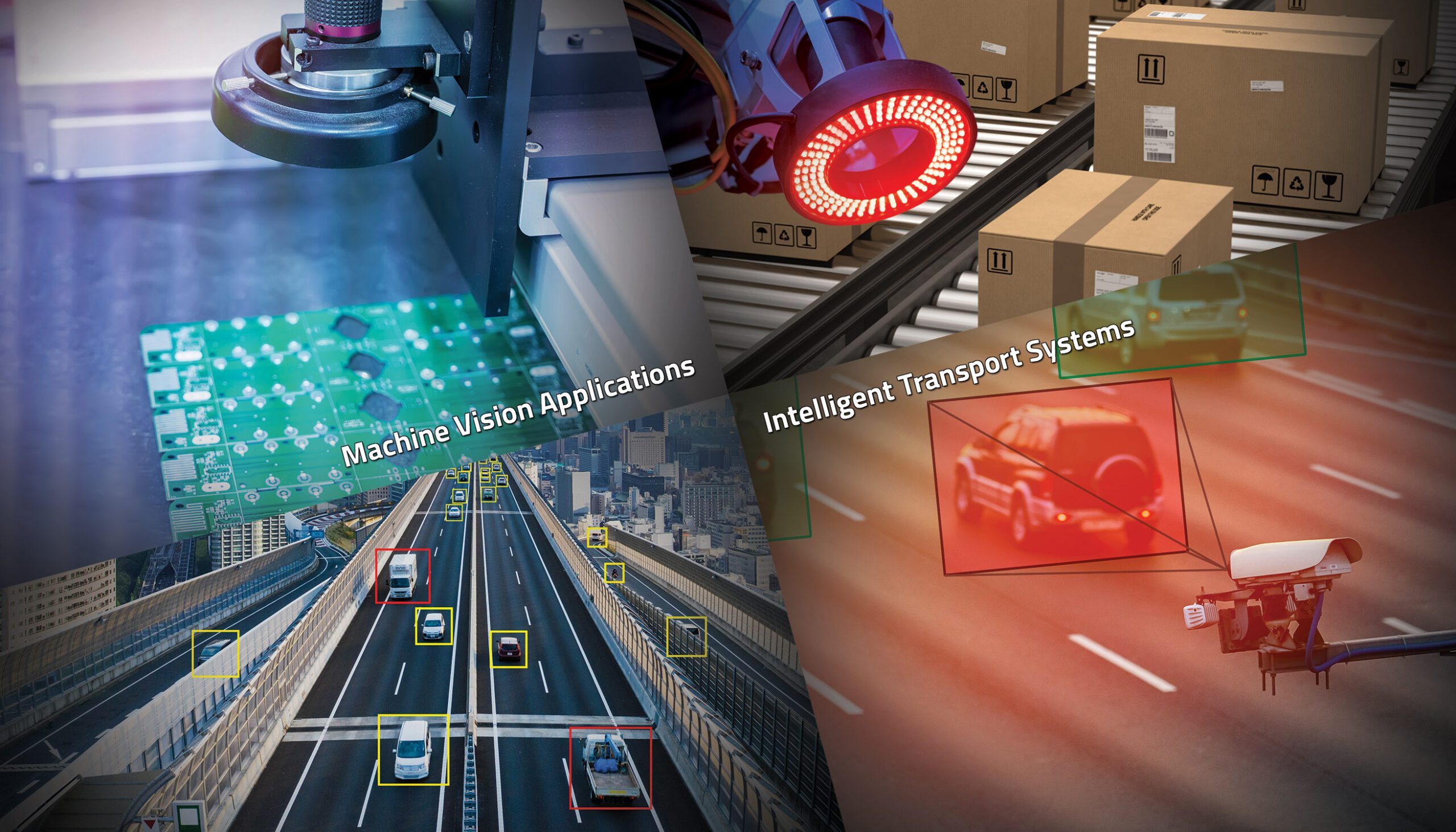

SANTA CLARA, Calif. — April 30, 2024 — OMNIVISION, a leading global developer of semiconductor solutions, including advanced digital imaging, analog, and touch & display technology, today announced the new OG09A10 CMOS global shutter (GS) sensor – the company’s first large-format GS solution for factory automation and intelligent transportation systems (ITS). The large-pixel, 3.45 µm backside-illuminated (BSI) stacked global shutter sensor, with its low readout noise and the highest quantum efficiency (QE) in its class, delivers excellent image quality, making it ideal for machine vision applications that require the ability to capture clear images of high-speed moving objects.

The OG09A10 is a 9-megapixel (MP) GS sensor with a 1-inch optical format. The sensor’s 3.45 µm pixel is based on OMNIVISION’s patented PureCel®Plus-S stacked-die architecture for best-in-class image sensor performance. The OG09A features Nyxel® near-infrared (NIR) technology for crisp, clear images in low-light conditions. Dual Conversion Gain High Dynamic Range (DCG™ HDR) technology further extends the GS image sensor’s dynamic range capabilities and reproduces artifact–free, low-noise images in challenging lighting conditions.

“Charge-coupled device (CCD) image sensors are being replaced with CMOS image sensors, resulting in volume growth of the machine vision market,” said Richard Liu, technology and market analyst for the Photonics, Sensing & Display Division of Yole Group. “CMOS greatly simplifies the complexity of industrial cameras. Compact cameras, including smart cameras, can more easily be developed and are more suitable for use in various industrial environments.” Liu adds, “With this being the case, Yole expects the global industrial camera market to grow from $3.6B in 2020 to $5.5B in 2026, at a 7.4% compound annual growth rate (CAGR)1.”

“OMNIVISION is the leading provider of image sensors to a number of markets, including security and surveillance, computing, medical, and emerging technologies such as AR/VR, so it is logical to carry our expertise into adjacent markets, such as factory automation and ITS, as part of our Machine Vision Unit,” said Kelly Yan, senior product marketing manager, OMNIVISION. “With the OG09A GS sensor, digital industrial cameras can now feature HDR support, high frame rates and higher resolution with better shutter efficiency.”

Key features of the new OG09A1B mono GS image sensor include:

- High shutter efficiency of 106 dB

- 90% QE response

- 76 dB dynamic range with Dual Conversion Gain (DCG™) HDR support

- High frame rate of 60 frames per second (fps) at 12‑bit (8×8 Region of Interest (ROI) reduces data bandwidth at even higher frame rates)

- 4096 x 2160 resolution

- External trigger mode enabling backend exposure control for improved accuracy

- Support for 16‑lane LVDS interface to 1.05 Gbps

The OG09A comes in a ceramic land grid array (CLGA) package. Samples of the OG09A10 color version and OG09A1B mono version are available now. For more information, contact your OMNIVISION sales representative: www.ovt.com/contact-sales.

Please visit OMNIVISION at the Automate Show, booth #4279, taking place May 6-9, 2024, McCormick Place, Chicago, Illinois.

1 Yole Intelligence, Machine Vision for Industry and Automation 2021.